Polyetherimide Ultem®* resin is a stiff, high strength thermoplastic material that exhibits long term heat resistance. It has the ability to withstand exposure to repeated cycles of steam sterilization. This high performance polymer features superior dielectric properties, extraordinary dimensional stability, resistance to stress cracking and a wide range of chemicals. Ultem® is difficult to ignite and has low smoke generation characteristics. Additionally, it is easily machinable in close tolerances. This amber transparent thermoplastic is also available in FDA compliant colors.

Ultem® is commonly used in the following industries:

- Pumps

- Healthcare

- Automotive

- Electrical

- Electronic

- Appliance

- Aerospace

- Defense

- Power and utilities

- Rail

Examples of specific applications are listed below:

- Medical respiratory device

- Analytical instrumentation

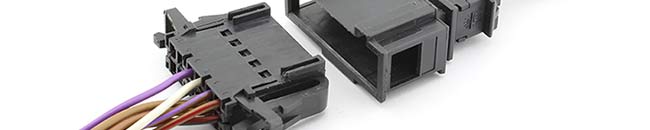

- Electrical connectors

- Electrical insulation parts

- HVAC equipment

- Sensors and thermostat housings

- Transmission components

- Fog light reflectors

- Electrical control units

- Water pump impellers

- Heat exchange systems

- Semiconductor process components

- Ignition components

- Switches capacitors

- Electromechanical systems

- Pump and valve parts

- Chemical processing equipment

- Medical monitor probe housings

- Aircraft parts

- Dental devices

Master Bond adhesive systems are utilized for bonding Ultem® to Ultem® and Ultem® to dissimilar substrates.

Consideration for Bonding Ultem® - High Temperature Resistance

Master Bond EP42HT-2Med, Supreme 10HT, Supreme 11AOHT, and EP3HTMed have been remarkably successful in bonding Ultem® polymers. EP42HT-2Med is a solvent free, two component ambient temperature curing system which can withstand repeated autoclave cycles. It meets UPS Class VI and ISO 10993-5 requirements. This system has good flow after mixing, impressive physical strength and adheres well to multiple similar/dissimilar substrates. Low outgassing NASA certified single component Supreme 10HT is serviceable from 4 K to 400°F. This toughened paste formulation has high peel/shear strength and is capable of withstanding thermal cycling. Master Bond Supreme 11AOHT is a thermally conductive, electrically insulative compound with a paste consistency. It passes MIL-STD-883J Section 3.5.2 for thermal stability. EP3HTMed is a no-mix product, cures quickly at 250-300°F and is desirable for producing reusable/disposable medical devices. This biocompatible system has an “unlimited” pot life and is serviceable up to 400°F.

*Ultem® is manufactured by SABIC.

For more information on bonding plastic substrates take a look at our surface preparation guide.

*Ultem® is manufactured by SABIC.