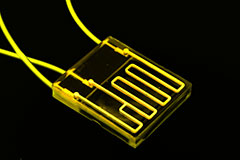

Microfluidic technologies are employed in a wide range of applications and scientific experiments, particularly in the life sciences, as an important tool for analysis and controlling of fluids. Useful across industries in shortening the lengths of experiments, reducing waste and providing measurements with improved accuracy, the demand for these versatile micro-devices with channels and chambers for fluid confinement is poised to continue growing undeterred.

Microfluidic technologies are employed in a wide range of applications and scientific experiments, particularly in the life sciences, as an important tool for analysis and controlling of fluids. Useful across industries in shortening the lengths of experiments, reducing waste and providing measurements with improved accuracy, the demand for these versatile micro-devices with channels and chambers for fluid confinement is poised to continue growing undeterred.

To ensure your microfluidic device is well-assembled for precise fluid manipulation, Master Bond offers a range of two component epoxies and UV curable systems that provide excellent chemical resistance, including noteworthy resistance to aggressive solvents and acids, cell culture media and aqueous solutions. These materials also offer negligible fluid absorption, resistance to elevated temperatures and good dimensional stability, the combination of which serves to minimize potential chemical interference in critical experiments.

Our two component epoxy and UV curable systems are suitable for both bonding substrates as well as for sealing or filling compact, hard-to-access areas between channels or edges. These solutions may also be used for coating, if desired. They offer good adhesion to a range of substrates often used in assembly of microfluidic devices, including, but not limited to, glass, silicon dioxide, PEEK, ceramic and acrylic.

For those applications that require particular adhesive properties, we have solutions that are USP Class VI rated, optically clear and low in viscosity as well. Our solutions can be applied in extremely thin bond lines and can be packaged in syringes for easy, controlled dispensing.

Master Bond EP41S-5 was used in a research article at University of Pennsylvania and Chonnam National University in Republic of Korea. Here is a quote from this paper:

Stainless steel compressed tube fittings (1/8 tube OD) form McMaster Carr (52245K609) are bonded to the glass wafer using chemically resistant epoxy from Master Bond (EP41S-5). The epoxy is left to cure at room temperature for 4 days. PTFE tubes of 1/8 OD were connected to the fittings."

Sources:

1Sagar Yadavali, Heon-Ho Jeong, Daeyeon Lee and David Issadore. Silicon and glass very large scale microfluidic droplet integration for terascale generation of polymer microparticles. Nature Communications, (2018) 9:1222. Accessed June 2016.